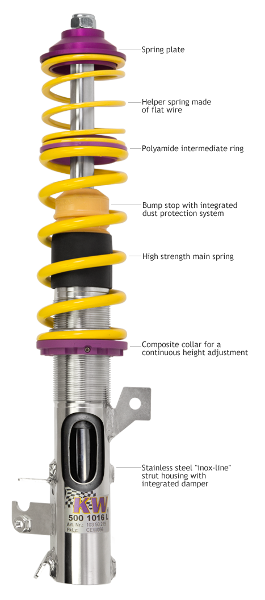

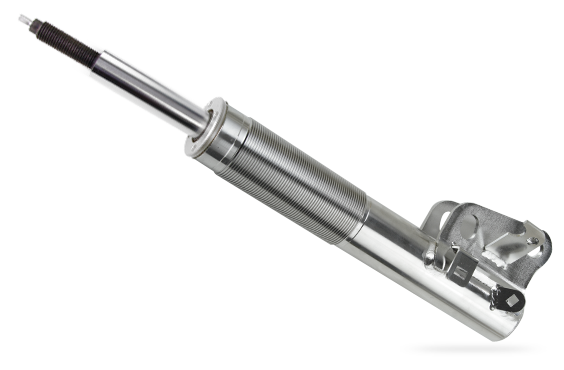

The KW coilover kit

Stepless lowering according to your wishes and high-quality components for a long service life

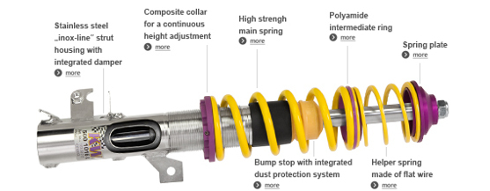

In contrast to conventional series and sports suspension solutions, a KW coilover kit has a trapezoidal thread and an adjustable spring plate. This allows a stepless lowering to be set.

Another difference to the conventional series suspension strut is the longer compression travel that the KW engineers achieve by using shorter, height-adjustable suspension strut housings. This means that the remaining spring travel is not impaired, even if the suspension is lowered to the maximum.

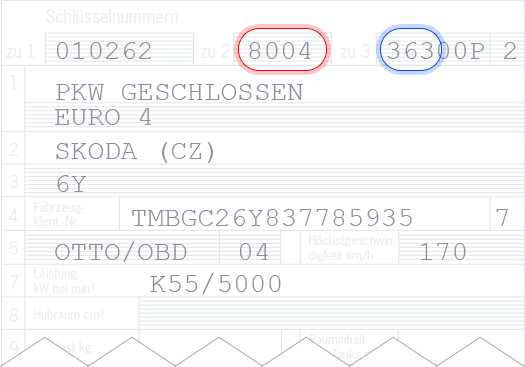

Stepless lowering

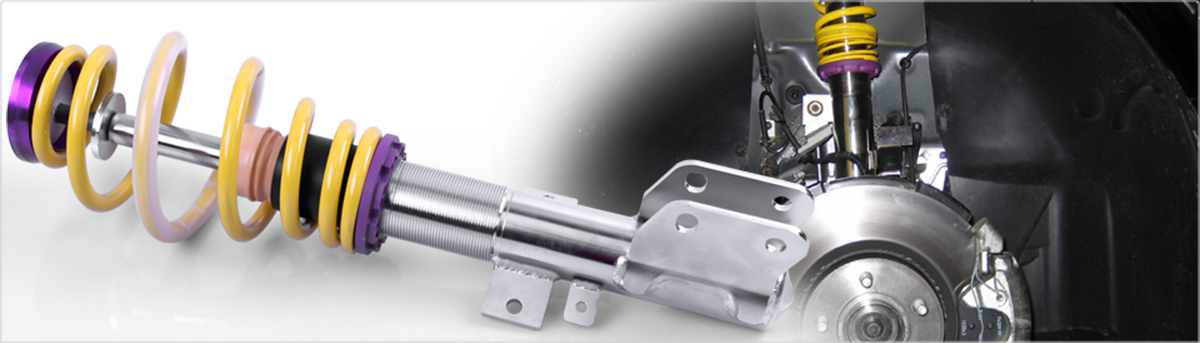

With a KW coilover kit "inox-line", the lowering of the installed chassis is adjusted on the 100 percent corrosion-resistant KW stainless steel strut according to the McPherson design. Due to the dirt-resistant trapezoidal thread and the durable polyamide threaded ring, changing the lowering is easy even after years of driving pleasure.

With the adjustment technology used by KW, this works even under spring preload. Depending on the vehicle type, the leveling of the lowering on the rear axle takes place either directly on the height-adjustable strut according to the McPherson design (e.g. Subaru Impreza); or via the KW rear axle height adjustment on the spring mount. In this case, too, the lowering can be adjusted quickly and easily when installed.

KW damper and KW spring

A coordinated unit for a sporty driving experience. High-quality components, a vehicle-specific damper production and tuning as well as many years of experience in the development of chassis for international motorsport characterize the KW damper technology.

The KW coilover kits for road vehicles are built according to the successful twin-tube damping principle, which is often also used in actively regulating series chassis. In twin-tube dampers, the piston housing (inner tube, also called rebound housing) and the differential housing (outer tube) are inserted into one another.

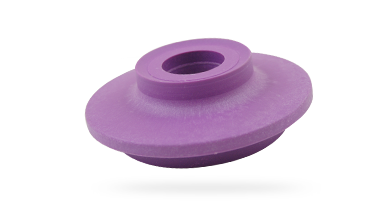

Spring plate

The KW spring plate is an often completely underestimated component. Not only does it hold the combination of preload and chassis springs in place, but it also minimizes the vibration noise of the springs. Depending on the vehicle type and field of application, KW manufactures the spring plate from a high-quality aluminum alloy or a polyamide composite material. Whether made of aluminum or the also resistant composite material, the spring plate, painted in the typical KW purple, has a low weight.

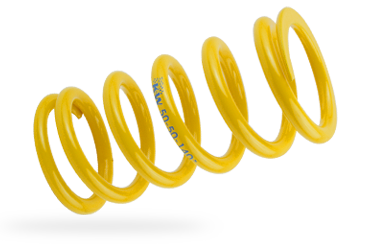

Preload spring

The so-called preload spring is made of high-quality chrome-silicon steel in flat wire design. It keeps the main spring under preload via the polyamide spring plate, regardless of the lowering level. As soon as the weight of the vehicle presses on the preload spring, all coils are pressed together - so to speak, "the spring goes into block".

Polyamide intermediate ring

The intermediate rings made of a light polyamide composite material used at KW not only serve as a support for the springs, but also minimize the vibration noise of the springs. In addition, they isolate road noise from the body.

Stop buffer with integrated dust protection system

The dust protection cap prevents splash water and dirt particles from penetrating the piston rod seal package. Depending on the vehicle type, the elastomeric dust cover also serves as a passive suspension element.

High strength main spring

Progressive spring rate

With a progressive spring rate, the chassis spring consists of spring coils of different hardness. When a force is applied, the weak windings give way first and then the harder spring windings. The same effect can also be achieved by using two linear springs placed one on top of the other.

Suspension spring

Not only the shock absorber or the vibration damper of a KW coilover kit influences the compression and rebound behavior, but also the KW spring. The resulting kinetic energy is stored by the spring during compression and converted into thermal energy by the damper.

The spring rate indicates how much force (N) has to act on the spring so that it is immersed by one millimeter. To put it simply: the higher the spring rate, the harder the spring and the more force must act on the spring to compress it.

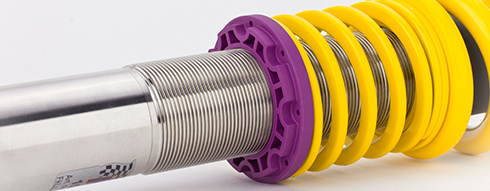

Polyamide threaded ring for stepless height adjustment

In contrast to anodized adjustable spring plates made of aluminum, KW uses a threaded ring made of a resistant polyamide composite material with a stainless steel insert. With anodized aluminum spring plates, it can happen that, after the lowering has been adjusted several times, barely visible microcracks occur due to the possible friction of dirt on the anodized surface. At these cracks, the unprotected aluminum threaded ring rests directly on the steel or stainless steel strut thread and oxidation occurs. In the worst case, the vehicle height can no longer be varied with conventional threaded rings. This is not the case with the durable KW coilovers in inox-line and the polyamide threaded ring used.

Stainless steel "inox-line" strut housing with integrated shock absorber

The strut housings of a KW coilover kit are made of high quality stainless steel and are an investment for the entire life of the car. In all weather conditions, the stainless, height-adjustable KW suspension struts are 100 percent corrosion-resistant and have an unlimited service life.

The functionality of the lowering via the dirt-resistant trapezoidal thread and the polyamide threaded ring is designed for long use. A salt spray test did not result in any oxidation on the height-adjustable KW suspension struts. So the stepless lowering is not affected even after years.